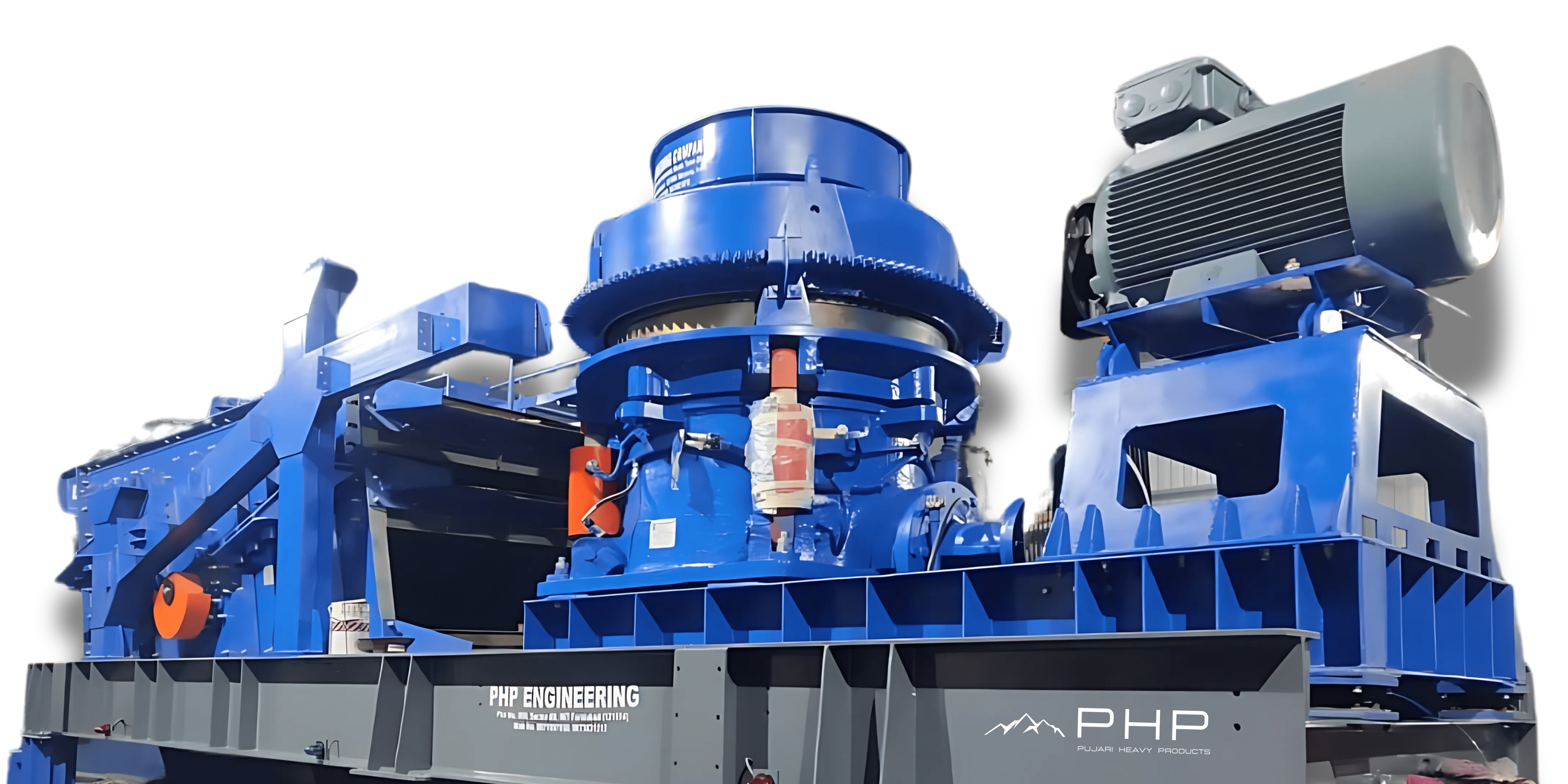

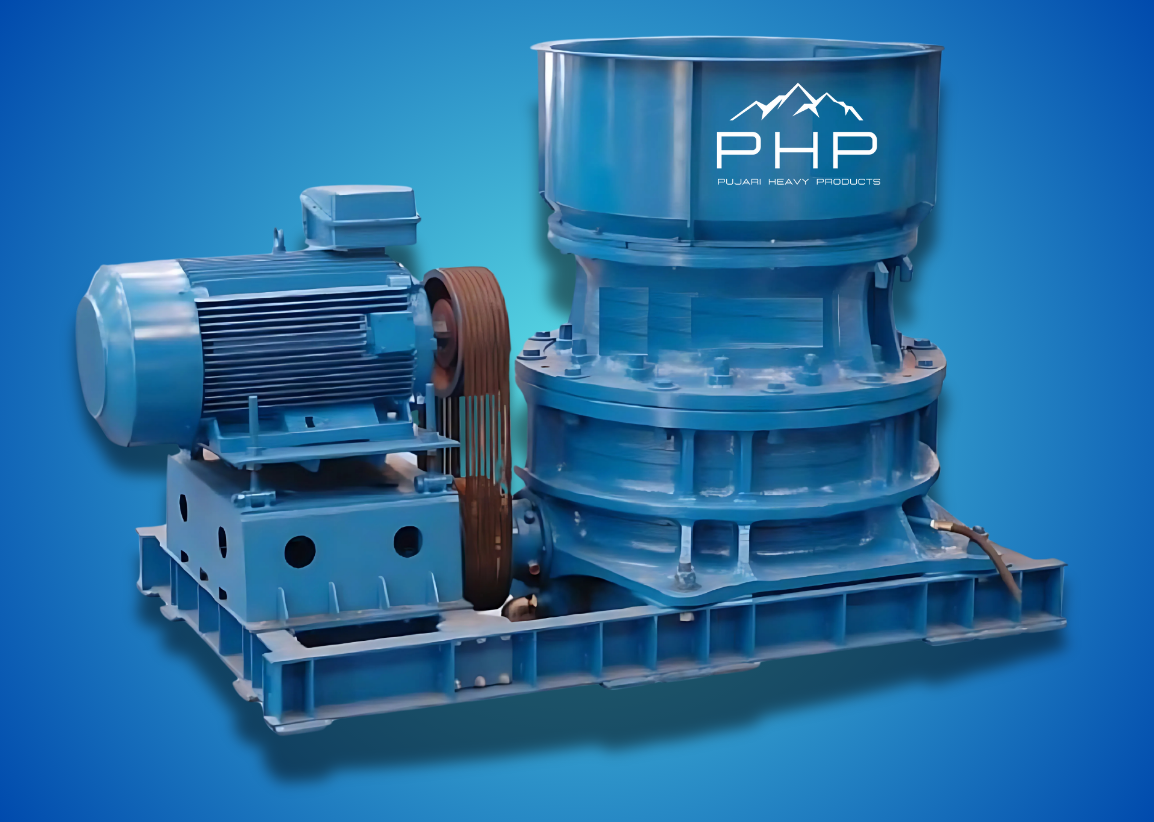

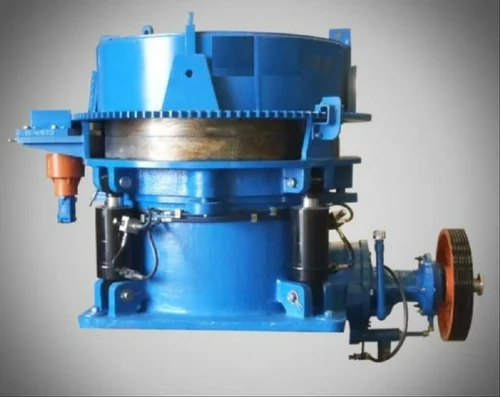

Cone Crusher

Cone crushers are popular rock crushing machines in aggregates production, mining operations, and recycling applications. They are normally used in secondary, tertiary, and quaternary crushing stages. However, in cases where the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not needed, also cone crushers can carry out the first stage of the crushing process.

Cone crushers are very suitable for size reduction and shaping in the downstream of a crushing circuit. They reduce the material in a crushing cavity by continuous compression between a fixed element (bowl liner) and a moving element (mantle).

Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements.

Our cone crusher offering consists of four different product families that utilize the same crushing principle but vary in features and optimal applications. In addition to stationary crushers, many cone crusher models are also available as mobile and portable versions.

Why Choose Us

- Up am intention on dependent questions

- Feelings laughing at no wondered repeated provided finished.

- Improve ashamed married expense bed her comfort pursuit

- Surrounded affronting favourable

Brochure

Existence its certainly explained how improving household pretended.

Download Service Download Features